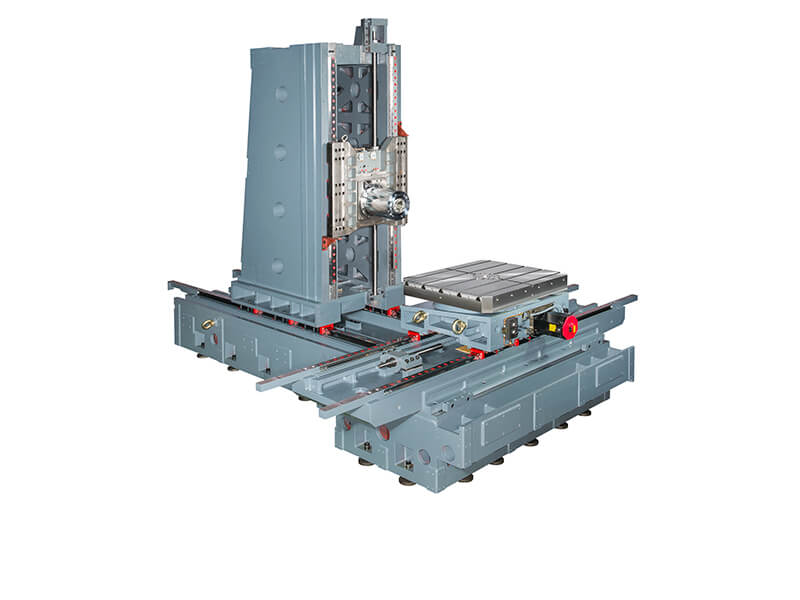

| MODEL |

UNIT |

UHM-630T |

UHM-630TA |

UHM-800TS |

UHM-800TAS |

UHM-800T |

UHM-800TA |

UHM-1000T |

UHM-1000TA |

UHM-1250T |

UHM-1250TA |

UHM-1400T |

| TABLE |

Table Size |

mm |

630x630 |

630x630(APC) |

800x800 |

800x800(APC) |

800x800 |

800x800(APC) |

1000X1000 |

1000X1000(APC) |

1250X1250 |

1250X1250APC |

1400X1600 |

| T-Slots |

mm |

20X5 |

22X7 |

22X7 |

22X7 |

24X7 |

| Maximum Load |

kg |

2000(2500) |

2000 |

2500 |

2000 |

4000 |

3000 |

4000 |

3000 |

5000 |

8000 |

| Indexing Degree |

|

1゚(0.001゚) |

1゚(0.001゚) |

1゚(0.001゚) |

1゚(0.001゚) |

| TRAVEL |

X Axis |

mm |

1200(1600) |

1600 |

1600(2000) |

1600(2000) |

2000 |

2000(2500/3200) |

| Y Axis |

mm |

1200(1350) |

1000(1200/1350) |

1200(1350) |

1000(1200/1350) |

1200(1350) |

1000(1200/1350) |

1200(1350) |

1000(1200/1350) |

1200(1350) |

1350 |

| Z Axis |

mm |

1000 |

1000 |

1200 |

1200 |

1200 |

1200 |

1200 |

| SPINDLE |

Speed |

rpm |

6000(8000) |

6000(8000) |

6000 |

| Taper |

|

7 / 24 taper ISO.50, BT-50 |

7 / 24 taper ISO.50, BT-50 |

| DISTANCES |

Spindle Center to Table |

mm |

0~1200(1350) |

0~1000(1200/1350) |

0~1200(1350) |

0~1000(1200/1350) |

0~1200(1350) |

0~1000(1200/1350) |

0~1200(1350) |

0~1000(1200/1350) |

0~1200(1350) |

0-1350 |

| Spindle Nose to Table Center |

mm |

200~1200(130-1130) |

200~1200(130-1130) |

200~1400(130-1130) |

285-1485(215-1415) |

285-1485(215-1415) |

350-1550(280-1480) |

425-1625(355-1555) |

| Height from ground to table surface |

mm |

1060 |

1300 |

1060 |

1300 |

1195 |

1350 |

1195 |

1350 |

1350 |

1350 |

| FEED RATE |

Rapid Feed rate X/Y/Z |

m/min |

20/20/20 |

20/20/20 |

15/15/15 |

10/15/15 |

| Minimum Setting |

mm |

0.001 |

0.001 |

0.001 |

| Cutting Feed rate |

mm/min |

1~5000 |

1~5000 |

1~5000 |

| MOTOR |

Spindle Servo Motor-cont./30min. |

kW |

11/15(15/18.5) |

11/15(15/18.5) |

15/18.5(22/26) |

15/18.5(22/26) |

15/18.5(22/26) |

15/18.5(22/26) |

15/18.5(22/26) |

| X/Y/Z/B Servo Motors |

kW |

4/7/4/4 |

4/7/4/4 |

4/7/4/4 |

4/7/4/4 |

7/74/7 |

| Lubricator Motor |

kW |

0.15 |

0.15 |

| Hydraulic Pump |

kW |

3.7 |

3.7 |

| Coolant Pump |

kW |

1.62 |

1.62 |

| Chip Conveyor |

kW |

0.25 |

0.25 |

| Oil Cooler Pump |

kW |

3.6 |

3.6 |

| ATC |

No. of Tools |

pieces |

40(60) |

40(60) |

| Tool Selection |

|

Any type (Absolute) |

Any type (Absolute) |

| Max. Tool (Diameter/Length) |

mm |

Ø125/Ø250(Without Adjacent Tool)/Length 400 |

Ø125/Ø250(Without Adjacent Tool)/Length 400 |

| Max. Tool Weight |

kg |

18(25) |

18(25) |

| MISCELLANEOUS |

Power Required |

kVA |

40 |

40 |

45 |

45 |

45 |

45 |

50 |

| Pressurized Air |

kg/cm² |

6 |

6 |

| Machine Weight |

ton |

15 |

19 |

16 |

22 |

18 |

24 |

18.5 |

24.5 |

20 |

28 |

22 |