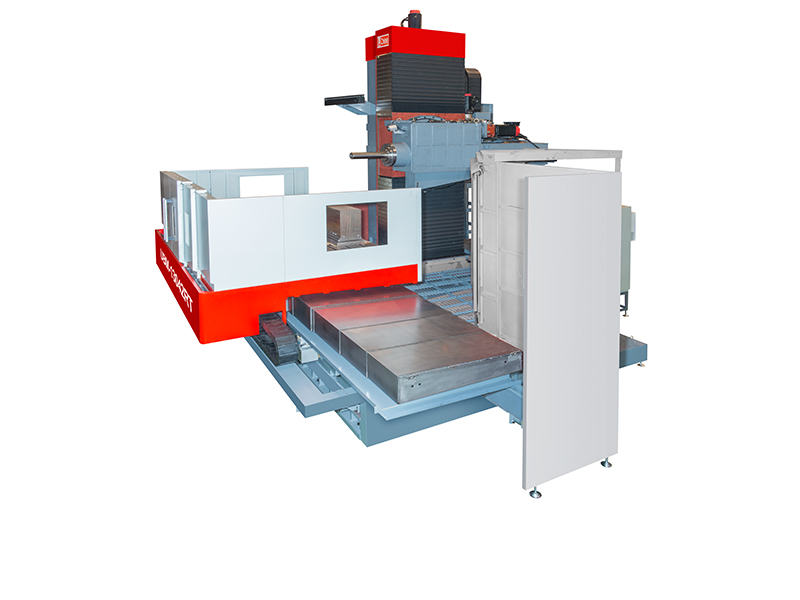

UBM CNC Horizontal Boring & Milling Mahcine Inquiry

> UBM RT

-

Features:

- Moving column structure. X axis and Z axis are independent and their accuracy an be adjusted individually.

- Upon customer request, a seletion of various loads (8 ~ 20 tons) of tables are available.

- Highly rigid column combined with mechanical counter-balance weight on Y axis provide higher stability and accuracy.

- Friendly working space prevents coolant and chips from splashing to the operator even with a high pressure coolant through spindle.

- Choice of Ø110mm and Ø130mm of spindle diameter.

-

MODEL UNIT UBM-11020RT UBM-11025RT UBM-11032RT UBM-11042RT UBM-13020RT UBM-13025RT UBM-13032RT UBM-13042RT TABLE Table Size mm 1600x1400 x0.001° 1600x1400 x0.001° T-Slots mm 24x7 24x7 Maximum Load kg 8000 8000 TRAVEL X Axis mm 2000 2500 3200 4200 2000 2500 3200 4200 Y Axis mm 1800 2000(2500,3000) Z Axis mm 1700 2000(2500) W Axis mm 500 700(900) SPINDLE Diameter mm Ø 110 Ø 130 Speed rpm 10~2500(3000)(4000) 10~2000(2500)(3000) Taper 7/24 taper, ISO.50, BT-50 7/24 taper, ISO.50, BT-50 DISTANCES Spindle Center to Table mm 0~1800 0~2000(0~2500,0~3000) Spindle Nose to Table Center mm 0~2200 -150~2250 Height from ground to table surface mm 1250 1260 FEED RATE Rapid Feed rate X/Y/Z m/min 10 10 Rapid Feed rate W m/min 10 6 Minimum Setting mm/min 0.001 0.001 Cutting Feed Rate mm/min 1~5000 1~5000 MOTOR Spindle Servo Motor kW 15/18.5 (22/26) 15/18.5 (22/26) Axis X / Y / Z / W / B kW 7/4/4/4/7 7/7/7/4/7 Lubricator Motor kW 0.15 0.15 Hydraulic Pump kW 2.25 2.25 Coolant Pump kW 1.17 1.17 Chip Conveyor kW 0.2 0.2 Oil Cooling Pump kW 0.75 0.75 ATC No. of Tools pieces 40(60) 40(60) Tool Selection Absolute Absolute Tool Change Time Sec. 15 15 Max. Tool-Diameter/Length mm Ø 125/ Ø 250(Without Adjacent Tool)/ Length 400 Ø 125/ Ø 250(Without Adjacent Tool)/ Length 400 Max. Tool Weight kg 25 25 COOLANT&LUBRICATION Coolant Tank Volume L 400 400 Hydraulic Tank Volume L 80 80 Lubrication Tank Volume L 8 8 MISCELLANEOUS Power Required kVA 55 55 Pressurized Air kg/cm² 6 6 -

standard accessories:

- Linear scale on X,Y,Z axes

- Spindle oil cooler

- Automatic power off

- Hydraulic system

- Coolant system

- Lubricator system

- Alarm lamp

- Work lamp

- M.P.G.

- RS232 interface

- Heat exchanger

- Chip conveyor and cart

- Leveling bolts & pads

- Controller manuals and circuit diagram

- Operation manuals

- Machine inspection lists

- Splah guards (around the table)

- Toolbox

- FANUC 0i-MF

- ATC : 40 Tools

optional accessories:

- ATC:60 Tools

- Oil mist device

- Variety of controllers {FANUC / MELDAS / SIEMENS / HEIDENHAIN}

- Various auxiliary work tables are available

- Air conditioner at the electrical cabinet

- Extension sleeve 250mm / 300mm

- Coolant through spindle

- 1800x1600x0.001 rotary table loading capacity 10tons

(For UBM-110xxRT series only) - Manual 90 angular milling head

- Simultaneously controlled rotary table